Geomembrane

Products Description

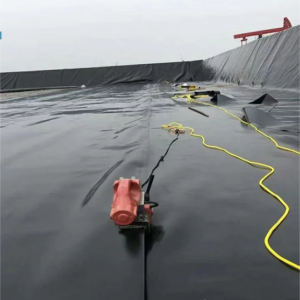

Geomembrane is polyethylene and other polymer materials blow molding, according to the production of raw materials can be divided into low density polyethylene (LDPE) geomembrane, high density polyethylene (HDPE) geomembrane and EVA geomembrane and other products such as high strength, aging resistance, good welding performance, convenient construction.It is mainly used for seepage prevention projects of channels, sewage treatment ponds, wharf projects, river dike reservoirs, lake DAMS, subways, landfill sites, etc.

Terms&Conditions

1. Product Name: Geomembrane

2. Raw material: LDPE (Low Density Polyethylene); LLDPE (Linear Low Density Polyethylene); HDPE (High Density Polyethylene); EVA

3. Color: Black, White, Blue, Green (Customized)

4. Thickness: 0.1mm-3.0mm

5. Width: regular 6m (Customized)

6. Function: Antioxidant; UV resistant

7. Production time: about 7 days after receiving the deposit.

8. More services: recommendations, routes to large transportation companies, installation guidance, including online videos and offline technical manager guidance.

2. Raw material: LDPE (Low Density Polyethylene); LLDPE (Linear Low Density Polyethylene); HDPE (High Density Polyethylene); EVA

3. Color: Black, White, Blue, Green (Customized)

4. Thickness: 0.1mm-3.0mm

5. Width: regular 6m (Customized)

6. Function: Antioxidant; UV resistant

7. Production time: about 7 days after receiving the deposit.

8. More services: recommendations, routes to large transportation companies, installation guidance, including online videos and offline technical manager guidance.

|

Item

|

Index

|

||||||||||||||||

|

Thickness (mm)

|

0.3

|

0.5

|

0.75

|

1

|

1.25

|

1.5

|

2

|

2.5

|

3

|

||||||||

|

Density (g/cm³)

|

≥0.94

|

||||||||||||||||

|

Tensile yield strength(MD/CD)

(N/mm)≥ |

4

|

7

|

10

|

13

|

16

|

20

|

26

|

33

|

40

|

||||||||

|

Tensile fracture strength(MD/CD)(N/mm)≥

|

6

|

10

|

15

|

20

|

25

|

30

|

40

|

50

|

60

|

||||||||

|

Yield elongation(MD/CD) %

|

≥11

|

|

|

|

|

|

|||||||||||

|

Elongation at break(MD/CD) %

|

≥600

|

|

|

|

|

|

|

|

|

||||||||

|

Right Angle tear load (MD/CD)N≥

|

34

|

56

|

84

|

115

|

140

|

170

|

225

|

280

|

340

|

||||||||

|

Puncture resistance

N≥ |

72

|

120

|

180

|

240

|

300

|

360

|

480

|

600

|

720

|

||||||||

|

Carbon black content %

|

2.0-3.0

|

||||||||||||||||

|

Dispersion of carbon black

|

In the 10 data levels, level 3 < 1, level 4 and level 5 are not allowed

|

||||||||||||||||

|

Atmospheric oxidation induction time(OIT)min

|

≥60

|

||||||||||||||||

|

Low temperature impact embrittlement

properties |

PASS

|

||||||||||||||||

|

Water vapor permeability coefficient g·cm/(cm2·s·Pa)

|

≤1.0 × 10-13

|

||||||||||||||||

|

Dimensional stability %

|

±2.0

|

||||||||||||||||

Details Images

Product packaging

Installation Instructions

Reviews

There are no reviews yet.